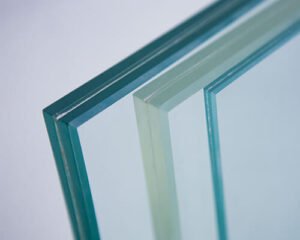

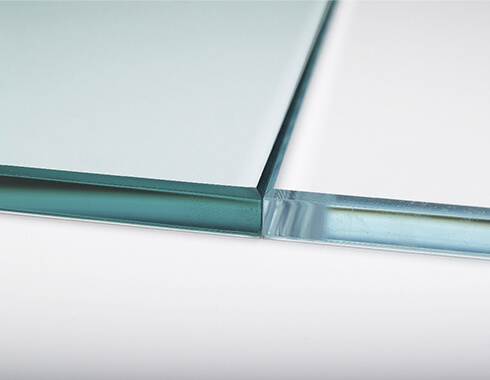

Float glass is a flat, transparent sheet of glass made by floating molten glass on a bath of molten tin. Also known as flat glass, annealed glass, or soda-lime glass, it’s widely used in windows, doors, mirrors, furniture, automotive glass, solar panels, and electronic displays. It also serves as the base for tempered, laminated, and coated glass products.

Introduction

When you think of glass — the kind in windows, doors, mirrors, or even your phone screen — you probably picture something smooth, clear, and flat. But have you ever wondered how that glass gets so perfectly level and transparent? Or why it’s strong enough to handle wind, weather, and daily use without warping or breaking?

That’s not just any glass — that’s float glass, and it’s the backbone of modern buildings, vehicles, electronics, and more.

But what makes this kind of glass so widely used? That’s where things get interesting. It isn’t just about being clear or flat — though those help. It’s the float glass production process that gives it such reliable quality and versatility. Once you understand how it’s formed and why that matters, you’ll start to see why it shows up in so many different places.

What Is Float Glass?

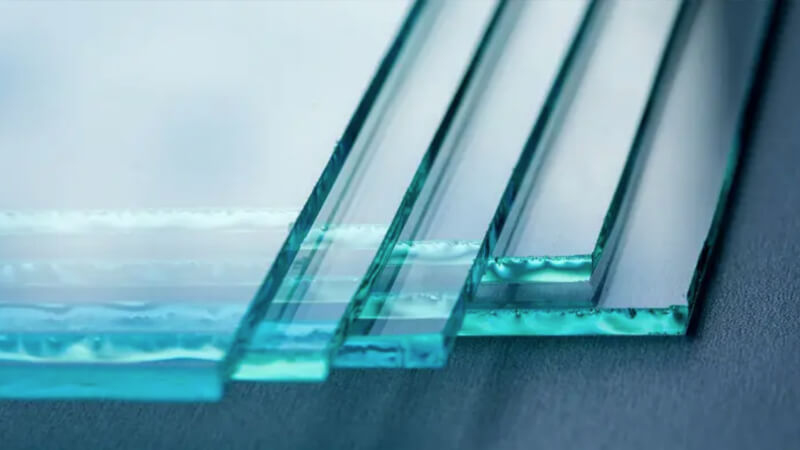

Think of molten glass being poured onto a bed of liquid tin. The glass doesn’t sink — it floats. And as it floats, it spreads itself into a perfectly even sheet, guided by gravity and surface tension. Smooth, flat, and clear. That’s where the name float glass comes from — and why it changed the way we use glass today.

Before this process, making flat glass was slow and imprecise. Sheets had to be rolled, ground, and polished by hand. With the float method, glassmakers could produce large, flawless panels — uniform in thickness, crystal-clear, and ready to use. It was a turning point for modern construction, design, and manufacturing.

Float glass is also known by other names:

- Flat glass — for its smooth, planar surface

- Annealed glass — because it’s slowly cooled to reduce internal stress

- Soda-lime glass — based on its key ingredients: silica sand, soda ash, and lime

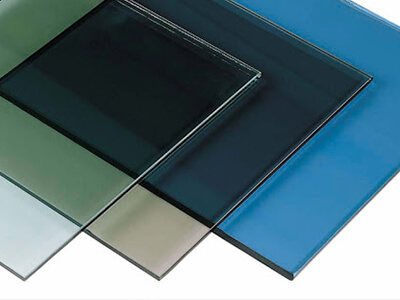

At its core, float glass is a starting point — a base layer. It can be strengthened, laminated, tinted, coated, or combined into high-performance systems. But no matter where it ends up — in a skyscraper, a windshield, or a solar panel — it begins here, with this precise and quietly elegant sheet of glass.

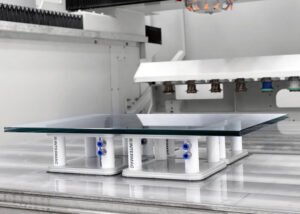

How Is Float Glass Made?

Float glass starts with something simple: sand, soda ash, and limestone. On their own, they’re just powdery raw materials. But when heated to over 1,500°C in a furnace, they melt into a thick, glowing liquid — something like molten honey, but far hotter and heavier.

This liquid glass is then carefully poured onto a bath of molten tin. Because glass is lighter than tin, it doesn’t sink — it floats. As it spreads across the tin’s surface, gravity and surface tension do something clever: they level the glass into a perfectly smooth sheet, without the need for rollers or polishing.

Once shaped, the glass travels through a long tunnel where it cools down gradually — a process known as annealing. This slow, controlled cooling relieves internal stress, so the final glass isn’t brittle or prone to cracking. Instead, you get a clear, strong, uniform sheet, ready to be cut or processed further.

That’s the float process — efficient, elegant, and still the global standard for producing high-quality flat glass.

Top 6 Uses of Float Glass (With Examples)

Float glass is like a silent partner in many parts of daily life. It’s not usually front-and-center, but it often sets the stage for something important — be it safety, comfort, or clarity. Let’s explore six places where it plays a pivotal, quietly reliable role.

1. Architecture & Construction

Buildings rely on float glass not just because it’s clear, but because it’s consistent and easy to work with.

- Windows and doors – Bring in light with clean transparency.

- Curtain walls and facades – Wrap buildings in a seamless glass skin.

- Skylights and overhead glazing – Bathe interiors in daylight.

- Partitions and railings – Keep spaces open yet safe.

Most of the time, float glass gets an extra treatment — tempered for strength, laminated for safety, or turned into insulated units to cut back on heat loss. Essentially, builders take that flat sheet and tailor it to the job — without losing its clarity or consistency.

2. Automotive Glass

Ever wonder why your windshield doesn’t shatter into dangerous shards? Or how your side window pops out in small chunks if it breaks?

- Windshields – Use laminated float glass — two layers of glass bonded together with plastic — to keep the glass in place during impact.

- Side and rear windows – Typically made of tempered float glass. If they break, they crumble safely.

- Mirrors – Both inside and outside the car, start with flat float glass before getting a reflective coating.

The key is that float glass provides the base clarity and uniformity. Then mechanics adapt it into something that keeps you safe on the road.

3. Furniture & Interior Design

Float glass turns into pieces that make spaces feel lighter and more open.

- Tabletops and shelves – Offer a clean, sturdy surface.

- Mirrors – Come alive when a thin metal layer is added to float glass.

- Cabinet doors, partitions, and frameless showers – Benefit from its adaptability and sleek look.

Here’s what’s neat: these interior pieces often use tempered float glass — so the glass is safe even if someone bumps into it. It’s both beautiful and practical.

4. Electronics & Displays

Almost every screen you look at started as float glass in a factory.

- Smartphones, tablets, and laptops – Rely on its flatness for accurate touch response.

- Monitors and televisions – Need it for clear visuals.

- Scanner beds – Use it to capture detail precisely.

Often, this glass is chemically strengthened to resist scratches and drops. Straight out of the float-line, it already has the perfect surface — it just needs a little extra resilience for everyday use.

5. Solar Panels

Here’s a quieter but critical role for float glass — it acts as the protective window over solar cells.

- Low-iron float glass – Allows more sunlight through, improving efficiency.

- Tempering – Ensures it can endure hail, wind, and debris.

So, even though it looks like “just glass,” it actively boosts power output and protects what’s inside. That makes it an unsung hero of sustainable energy.

6. Specialty & Industrial Uses

Float glass finds itself in surprising places — all because it starts strong and clear.

- Greenhouses – Rely on its light transmission.

- Display cases – In museums use it for undistorted viewing and UV protection.

- Appliances – Like oven doors and fridge shelves, benefit from its heat resistance.

- Fire-rated or bullet-resistant systems – Pair float glass with special layers for added protection.

In all these cases, the base material stays the same. Float glass provides reliability — then engineers build on it for the job at hand

Key Features and Benefits of Float Glass

Float glass might look simple, but it’s packed with useful traits. The reason it works so well in so many places — from a windowpane to a phone screen — lies in how it behaves once it cools.

Here’s a closer look at the features that make float glass such a trusted material.

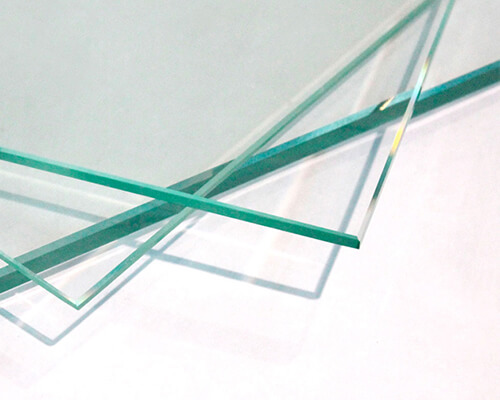

Exceptional Flatness

When molten glass floats on liquid tin, it settles like water in a still pond.

No rollers, no grinding — just natural smoothness shaped by gravity and surface tension.

That perfect flatness makes it ideal for mirrors, glazing, and anything where clarity counts.

Uniform Thickness

As the glass spreads over the tin bath, it forms a consistent layer — edge to edge.

That means no weak spots, no bulges, no uneven stress.

For architects and engineers, that kind of reliability is gold.

High Optical Clarity

Standard float glass transmits up to 90% of visible light — clean and color-neutral.

It gives you a true view through a window and keeps interiors bright.

That clarity supports both design and energy performance, without distortion.

Workability

Float glass plays well with tools.

It’s easy to cut, shape, drill, or process further — without splintering or cracking.

More importantly, it’s the starting point for tempered, laminated, or coated glass.

Chemical Stability

Glass may seem fragile, but float glass holds up.

It resists moisture, UV light, and most chemicals in the air or rain.

That’s why it lasts in outdoor facades, greenhouses, and appliances alike.

Scalable and Efficient

The float process doesn’t just make good glass — it makes it at scale.

Factories can run continuously, producing huge volumes without compromising quality.

That’s how float glass stays affordable while meeting demanding standards.

Float glass earns its place by doing something rare: it combines precision, versatility, and durability — all in one clean, clear sheet. Whether it stays simple or gets turned into something more advanced, these are the traits that make it work.

Conclusion

Float glass isn’t flashy — but it’s essential. It provides a clear, consistent base that modern design depends on. Whether it’s in a skyscraper, a smartphone, or a solar panel, float glass offers the reliability and versatility that few materials can match.

And once you know what to look for, you start seeing it everywhere — in buildings, devices, and spaces all around you. It works quietly in the background, doing exactly what it was made to do.

From buildings to devices, float glass doesn’t just support modern design — it makes it possible.

FAQs about Float Glass

1. How do I choose the right type of float glass?

It depends: standard float for interiors, tempered or laminated for safety and strength.

Consider location, load, and whether coatings are needed. Different types suit architectural, industrial, or interior needs.

2. Can float glass be used on building facades?

Yes — when processed, float glass performs well in facades, curtain walls, and glazing systems.

It’s typically tempered, laminated, or insulated. Used widely in commercial and high-rise construction.

3. Can float glass be coated (Low-E, reflective)?

Yes, float glass is the base for Low-E and reflective coatings.

These improve insulation and light control. Common in facades, skylights, and green buildings.

4. Does float glass help with sound insulation?

Yes — when laminated or used in IGUs, float glass helps block airborne noise.

Ideal for offices, hospitals, and homes in noisy urban environments.

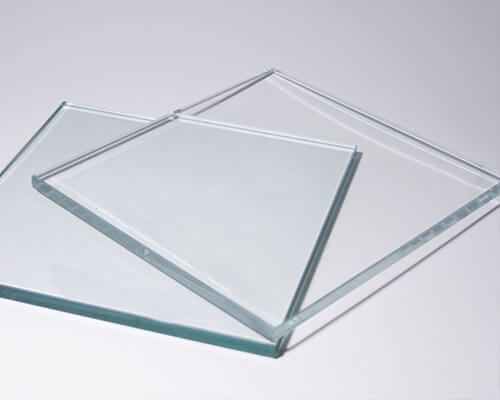

5. What thicknesses are used in architecture and interiors?

Typical ranges are 3–19 mm:

5–12 mm for glazing, 10–19 mm for safety or load-bearing.

Thickness depends on span and structural needs.

6. What is the lead time for bulk float glass from China?

Usually 7–25 days, depending on processing and shipping.

Faster for standard specs or in-stock sizes. Sea freight and documents are often included.