Float glass is a clear, flat glass made by floating molten glass on a bed of molten tin to create perfectly smooth, parallel surfaces. Known for its high clarity, uniform thickness, and versatility, it’s the base material for most architectural, interior, automotive, and solar glass products.

Introduction

Imagine standing in front of a skyscraper with floor-to-ceiling windows, or looking into a bathroom mirror so smooth it feels like a pool of still water. Ever wonder what kind of glass makes that possible? That’s float glass — the unsung hero behind the sleek, transparent surfaces we rely on every day.

Float glass is everywhere. It’s in your windows, car windshields, tabletops, display cabinets — basically, if it’s flat and glass, chances are it’s float glass. But what exactly is it? How is it made, and why is it the go-to choice in modern architecture, design, and manufacturing?

In this guide, I’ll walk you through the basics of float glass: what it is, how it’s created, why it’s so useful, and where you’ll find it in the real world. No jargon, no fluff — just a clear, simple explanation to help you really get it.

What Is Float Glass and Why Does It Matter?

At its core, float glass is just flat glass. But not just any flat glass — it’s made with a process so precise, it creates sheets that are perfectly smooth, clear, and uniform in thickness.

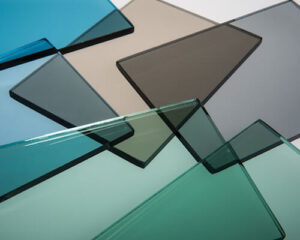

Think of float glass as the “blank canvas” of the glass world. It’s the raw form from which other specialized glass types are made — like tempered glass for your shower doors or laminated glass for your car windshield. But before any of those extra treatments happen, it all starts with float glass.

Now here’s the interesting part: the name “float” comes from how it’s made. Molten glass is poured onto a bath of molten tin, where it literally floats — like oil on water. Because tin has a high density and doesn’t mix with glass, the molten glass spreads out into a perfectly even sheet on top. It’s one of those brilliant yet simple ideas that transformed the glass industry when it was introduced in the 1950s.

So whenever you see a sheet of glass that’s impressively smooth and distortion-free, you’re likely looking at float glass. It’s not just functional — it’s the foundation for nearly every modern glass product you can think of.

How is Float Glass Made Step by Step?

Let’s break this down together — not in textbook terms, but in a way that actually makes sense.

Float glass starts its life as a fiery mixture of ingredients. Think of it like baking, but with sand. The main ingredient is silica sand, which is combined with things like soda ash and limestone. These raw materials are heated in a furnace to over 1,500°C — hotter than lava — until they melt into a glowing, honey-like liquid.

Now here comes the clever part.

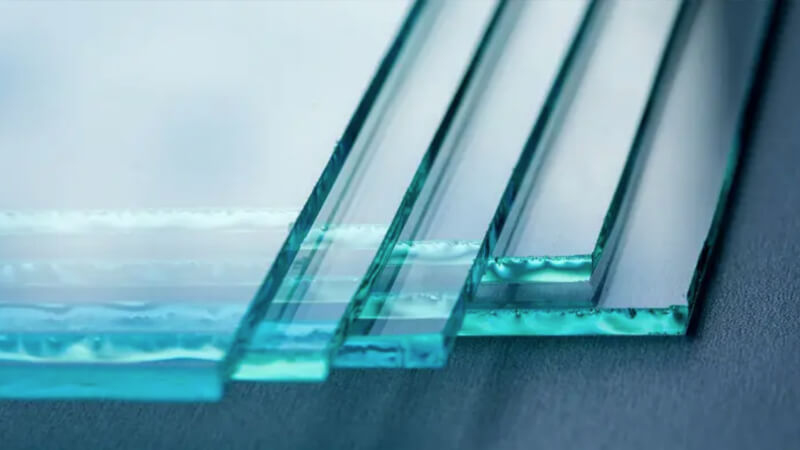

Instead of trying to roll or press this molten glass flat (which often led to uneven or bumpy surfaces in older methods), engineers figured out something genius: let it float. The molten glass is poured slowly onto a bath of molten tin. Because glass is less dense, it spreads out on top like oil floating on water. And since tin is perfectly smooth and level, the bottom of the glass becomes just as smooth.

While it floats, gravity and surface tension do the rest — smoothing the top surface naturally, no polishing needed.

The glass then moves through a long chamber called the annealing lehr, where it cools slowly and evenly. This step is crucial. If you cool it too fast, it cracks. If you let it cool too slowly or unevenly, you end up with weak spots. Annealing removes internal stresses and ensures the sheet is stable and strong.

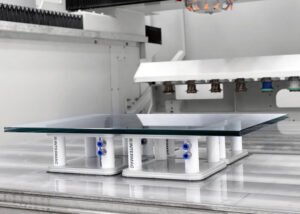

Finally, the now-solid sheet of float glass is cut into giant panels, inspected for defects, and sent off to be sold or processed further — tempered, laminated, coated, or customized depending on where it’s going.

The beauty of the float process is its simplicity. You’re letting physics — density, gravity, temperature — do the heavy lifting. And the result? A flawless sheet of glass, flat and crystal-clear, ready for just about anything.

What Are the Key Benefits of Float Glass?

So now that we know how float glass is made, let’s talk about why it matters. What makes it such a staple in everything from skyscrapers to smartphone screens?

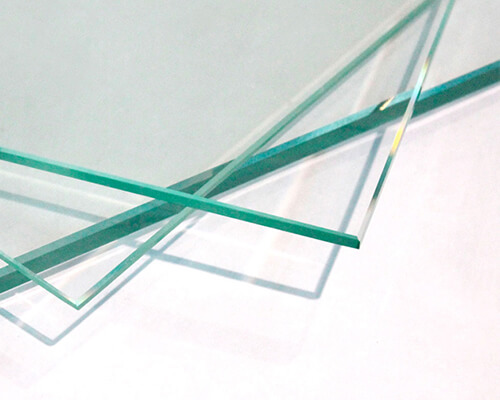

1. Perfect Flatness and Clarity

Because float glass forms on molten tin, the surface is incredibly smooth — like glass on water, quite literally. This means no distortions, no warping. Look through a window made of float glass, and you’ll see the outside world exactly as it is. That clarity is hard to beat.

Whether it’s a city skyline or a store display, float glass gives you that clean, sharp view you expect.

2. Versatility as a Base Material

Here’s the thing: float glass is a starting point. It’s like the raw canvas for all advanced glass products. Want a stronger version? Temper it. Want extra safety? Laminate it. Want to block UV or heat? Add a special coating.

No matter where it ends up — in a car, a window, or a piece of art — it usually begins as float glass.

3. Strength for Everyday Use

Even without extra treatments, float glass is tough enough for regular use. It won’t crumble in your hands or crack under normal pressure. It’s used in windows, tabletops, cabinet doors — places where impact isn’t extreme, but reliability matters.

And when treated further (like being tempered or laminated), it becomes suitable for high-stress, high-safety situations, too.

4. Cost-Effective and Scalable

One of the reasons float glass is everywhere is because it’s economical to make in large quantities. The float process is continuous, efficient, and produces high volumes with consistent quality. This keeps prices down — great for manufacturers and great for you.

5. Sustainable and Recyclable

Float glass is 100% recyclable. It can be melted down and re-formed without losing quality — again and again. In a world that’s becoming more environmentally conscious, this matters. Using recycled glass reduces energy usage and raw material consumption.

Want to explore both the pros and cons in more detail? Check out this guide on the advantages and disadvantages of float glass to see the full picture.

Where Can Float Glass Be Applied For?

Now that we know what float glass is and why it’s useful, let’s look at where you’ll actually find it.

Here’s the short version: everywhere.

But let’s break that down with a few real-life examples. Once you start noticing, you’ll see float glass just about every time you turn your head.

1. Buildings and Architecture

This is the big one. Float glass is a core material in modern construction.

Look at a city skyline — those sleek, shiny towers with massive glass façades? All float glass. Office buildings, apartment complexes, hospitals, schools — they all rely on it for windows, doors, skylights, and even full glass walls.

Why? Because float glass gives you clear views, lots of daylight, and a clean, minimal look architects love. It’s also easy to customize — you can tint it, coat it, or turn it into insulated glass units for energy savings.

And here’s something cool: many of the safety or energy-efficient windows you see today still started out as float glass before being tempered, laminated, or double-glazed.

2. Automotive Glass

Your car? Also full of float glass.

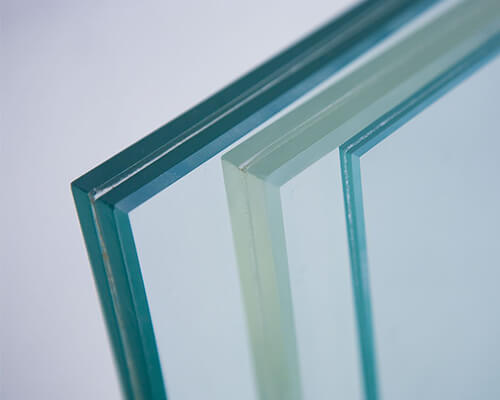

The windshield is typically laminated float glass — two layers of glass with a plastic layer in between. That way, even if a rock hits it, the glass doesn’t shatter into your lap.

The side and rear windows? Usually tempered float glass — stronger and safer than basic glass, but still made from the same original float process.

Even your car’s mirrors are float glass with a reflective backing. The flatness and clarity help ensure you get an accurate view of what’s behind you (no funhouse mirror effect when changing lanes, please).

3. Home Interiors and Furniture

Walk through any home or office, and you’ll spot float glass in the details.

Glass tabletops, shelves, cabinet doors, room dividers, and mirrors — all typically made from float glass. That perfect surface finish and see-through clarity make it ideal for both function and style.

It’s used in frameless glass doors, shower enclosures, and decorative panels too. Sometimes it’s frosted or etched, but the base is still float glass underneath.

Designers love it because it plays so well with light. It opens up spaces, reflects daylight, and adds that clean, modern touch.

4. Displays and Electronics

Though it’s a bit more specialized, float glass also finds its way into tech — as a base for LED display panels, touchscreens, and solar panels.

Why float glass here? Because the surfaces need to be extremely flat, especially when working with pixels and electronics that measure in microns. It’s a behind-the-scenes role, but it’s essential.

Conclusion

So, what’s the big idea behind float glass?

It’s the clear, flat sheet that underpins modern life. From your living room window to your car’s windshield, from a sleek skyscraper to a humble picture frame — float glass is the invisible structure that makes all of it possible.

And the real magic? It’s not just what it is — it’s what it can become.

Float glass is incredibly adaptable. It can be toughened, laminated, coated, curved, colored — you name it. But even before all those transformations, it’s already delivering clarity, strength, and simplicity.

Next time you look through a window, or catch your reflection in a mirror, take a second to appreciate the science and elegance behind that perfectly flat surface. Because now, you know — that’s float glass.

FAQs: Common Questions About Float Glass

1. What is float glass used for in construction and daily life?

Float glass is widely used in modern construction and interior design. You’ll find it in windows, glass doors, skylights, facades, mirrors, tabletops, shower enclosures, and cabinet doors. It’s also the base material for tempered and laminated glass, which are used in car windshields, safety glass, and energy-efficient windows.

2. How is float glass different from tempered glass?

Float glass is the untreated, raw form of glass with a flat, smooth surface. Tempered glass is float glass that has been heat-treated to become much stronger and safer. When broken, float glass shatters into sharp pieces, while tempered glass breaks into small, blunt fragments, making it safer for high-impact areas like shower doors or car windows.

3. Is float glass strong enough for windows or doors?

Yes, float glass is strong enough for standard windows and interior doors where impact risk is low. However, for areas that require safety compliance or extra strength — like glass railings, large exterior windows, or doors in public spaces — float glass is usually tempered or laminated to improve safety and durability.

4. Can you cut or drill float glass?

Yes, float glass can be cut or drilled — but only in its annealed (untreated) state. Once it’s been tempered, it becomes too brittle for cutting or drilling and will shatter. If you plan to modify float glass, make sure all cutting and shaping is done before any tempering process.

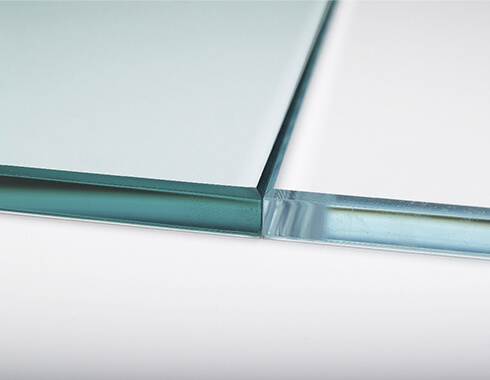

5. What are the standard float glass thickness options?

Float glass typically comes in thicknesses ranging from 2mm to 19mm. Common options include:

- 3mm–6mm for windows and picture frames

- 8mm–12mm for tabletops, partitions, and doors

- 15mm–19mm for structural or decorative panels

Custom thicknesses may also be available depending on your supplier.

6. Does float glass help with heat insulation or energy efficiency?

On its own, basic float glass is not highly energy efficient. However, when coated with Low-E layers, tinted, or used in double-glazed insulated glass units, float glass can significantly improve thermal insulation, reduce solar heat gain, and block UV rays — making it suitable for green building projects.

7. Is float glass an environmentally friendly material?

Yes. Float glass is 100% recyclable and can be melted down to make new glass products without losing quality. Using recycled float glass reduces energy consumption and helps lower the environmental impact of manufacturing, making it a sustainable building material.

8. How much does float glass cost per square meter?

The price of float glass varies depending on thickness, size, clarity, and whether it includes additional treatments (like tinting or coating). On average, basic float glass may cost between $5 to $15 per square meter, while specialty or thicker glass can go higher. For accurate pricing, it’s best to contact a local supplier or manufacturer.er. For accurate pricing, it’s best to contact a local supplier or manufacturer.