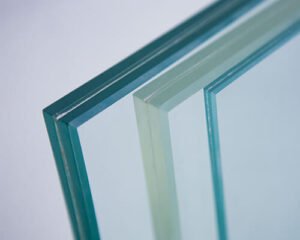

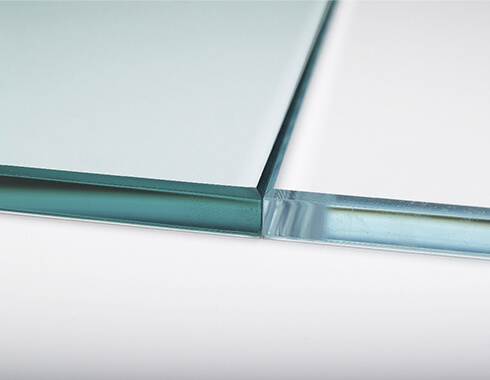

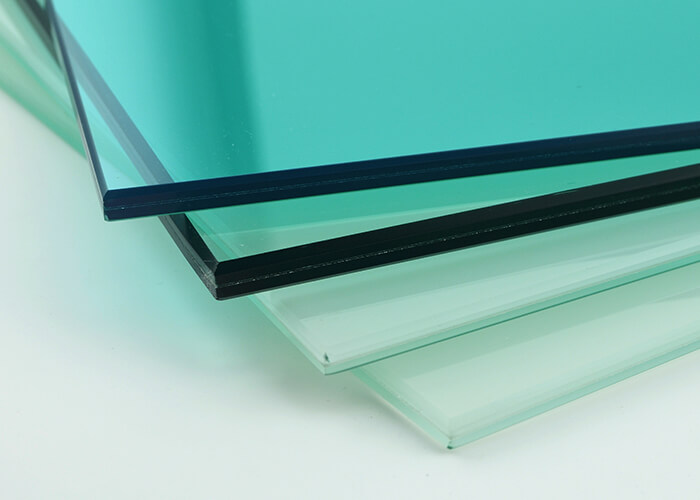

Laminated glass is two or more layers of glass sandwiched between a layer of polyvinyl butyral (PVB) interlayer and bonded together under high temperature and pressure. Laminated glass has high safety performance, even if the glass breaks, the fragments will not splash, effectively protecting personal safety.

As a practitioner with more than 20 years of experience in the glass industry, I’m always surprised when customers don’t understand how laminated glass is produced and how these production processes affect the final quality and price of laminated glass.

The following article will introduce the production process of how is laminated glass made in detail, as well as some questions related to laminated glass. So, let’s dive in!

Table of Contents

ToggleWhat is laminated glass?

Laminated glass acts as a guardian in the glass world. It is a kind of safety glass made of two or more layers of glass sheets and one or more layers of PVB interlayer, which are stacked and pressed under high temperature and high pressure.

The magic of laminated glass lies in its exceptional safety performance. Even if it shatters, it won’t break into hazardous shards, making it a steadfast protector of personal safety. Laminated glass also has high safety, shock resistance, anti-theft, bulletproof, and explosion-proof properties, as well as good energy conservation and sound insulation.

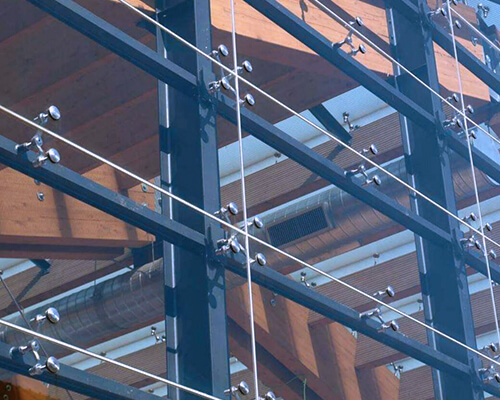

Laminated glass applications

Laminated glass is widely used in construction, transportation, industry and other fields. In the construction field, it’s a preferred choice for curtain walls, doors, windows, and partitions. In the transportation field, laminated glass is mainly used for automobile windshields and window glass. Meanwhile, in the industrial world, it shines as protective glass and sound insulation glass.

How is Laminated Glass Made?

So, how do they create this marvel of glass engineering? The production process of laminated glass generally includes the following six steps:

Glass Sheet Prep

First things first, you need to gather two or more glass sheets. The thickness, size and type of the glass sheets need to be selected according to the customer’s needs. Here you can choose the best glass solution for your project, no matter its for further processing, nor finished glass applications. These glass sheets should have no dirt, scratches or other defects on the glass sheets, otherwise the quality of the laminated glass will be affected.

Glass Cleaning

Cleaning the glass is an important step in the production of laminated glass. The purpose of cleaning is to remove dirt and dust from the glass sheets to ensure the bonding effect of the interlayer. Glass sheets are generally cleaned by spraying, brushing or ultrasonic cleaning.

Assembling the Interlayer

After the glass sheets are cleaned, it’s time to assemble the laminated glass interlayer. Two or more glass sheets and one or more layers of PVB interlayer will be assembled into a laminated glass. Typically, the PVB interlayer’s thickness hovers around 1.14 mm or 1.52 mm. The assembly can be done by hand or with the assistance of machines.

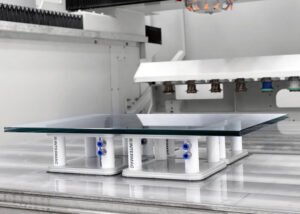

Bond the glass and interlayer with rollers

The laminated glass now will be moved into a roller machine, and the PVB interlayer is melted and bonded to the glass sheets by the squeezing and heating of the rollers. The heating temperature of the rollers is generally 145℃~150℃, and the pressure is generally 2~5MPa.

The Autoclave Stage

After the laminated glass was taken off from the laminated glass production line, you can still see a lot of bubbles inside. To fully eliminate the bubbles, now we put the bonded laminated glass into the autoclave. Now the PVB interlayer is completely disappeared and firmly bonded to the glass sheets under the action of high temperature and high pressure (temperature of 150℃~160℃, pressure of 10~15MPa).

Inspections, Packing and Delivery

After the laminated glass is finished in the autoclave, it still needs inspections before packaging before delivery. The packing of glass sheets is very important when delivering from China to your port. HEXAD uses comprehensive and safe packaging and loading to ensure your glass safety.

In Conclusion

There you have it, the detailed journey of laminated glass, from raw materials to a finished safety glass. I hope that through the above introduction, everyone has a deeper understanding of the production process of laminated glass. When choosing a supplier of laminated glass, it is recommended to choose an experienced and technologically mature manufacturer to ensure the quality of laminated glass.

But I’m sure you have some questions, so let’s dive into those.

Laminated Glass Q&A

Is laminated glass safety glass?

Yes, laminated glass is safety glass.

Safety glass is a type of glass that is designed to be less likely to break, or less likely to pose a threat when broken. It is commonly used in applications where there is a risk of injury from broken glass, such as in car windshields, building windows, and shower doors.

The PVB layer holds the laminated glass together even if it breaks, preventing the glass from shattering into sharp pieces. This makes laminated glass ideal for applications where safety is a concern, such as in car windshields, building windows, and shower doors.

Is laminated glass considered safety glazing?

Yes, laminated glass is considered safety glazing. Safety glazing is a type of glass that is designed to reduce the risk of injury in the event of breakage. Laminated glass meets the safety glazing requirements of most building codes.

Safety glazing is required by building codes in many jurisdictions for certain types of applications, such as windows and doors in schools, hospitals, and other public buildings. It is also recommended for use in homes and businesses to reduce the risk of injury from broken glass.

Can you cut or drill laminated glass?

Absolutely, you can, but it requires a delicate touch. Cutting or drilling laminated glass is possible, but it’s essential to use specialized tools and techniques to avoid damaging the glass. Keep in mind that these processes may weaken the glass’s structural integrity, so consulting a professional is advisable.

If you need the laminated glass to come with notches or holes, you can freely send us drawings and requirements, HEXAD can finish the whole process before shipping.

Is laminated glass tempered?

Laminated glass is not typically tempered. However, it is possible to temper laminated glass. Tempered laminated glass offers even greater strength and durability compared to regular laminated glass.

Can tempered glass be laminated?

Yes, tempered glass can be laminated. Laminated tempered glass is a type of safety glass that is made by bonding two or more layers of tempered glass together with a layer of PVB interlayer.

Laminated tempered glass is the strongest and safest type of glass available. It is often used in applications where there is a high risk of breakage or impact. It is also used in bullet-resistant glass and other security applications.

Laminated tempered glass is a more expensive option than regular glass, but it is a good investment for applications where safety and durability are a top priority.

I hope this information is helpful. If you have further questions or need additional information, please don’t hesitate to reach out.