Vacuum Insulated Glass (VIG) is a superior alternative to triple glazing, utilizing vacuum technology similar to a thermos to block heat transfer. By replacing gas-filled cavities with a vacuum, VIG delivers:

- 3x Better Insulation: R-20 performance vs. R-7 for triple glazing.

- 75% Thinner Profile: Just 8mm thick compared to 44mm.

- 50% Less Weight: 25 kg/m ² vs. 50 kg/m ², reducing structural load.

- Superior Longevity: No gases to leak over time implies a 25+ year lifespan.

The Problem with Modern Windows

Here’s a problem architects have been wrestling with for the past decade: everyone wants floor-to-ceiling glass, but energy codes demand serious insulation.

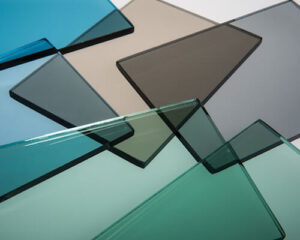

The solution has been triple glazing, and while it works for keeping heat in, it’s heavy, bulky, greenish-tinted, and requires chunky frames that fight against modern minimalist design. Architects have been stuck choosing between energy performance and the clean aesthetic they’re actually trying to achieve.

Vacuum Insulated Glass—VIG—eliminates this compromise entirely. Once you understand the physics behind it, you’ll see why this technology is poised to become the new standard for high-performance buildings.

What is Vacuum Insulated Glass?

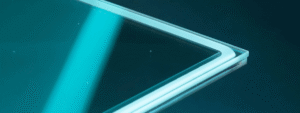

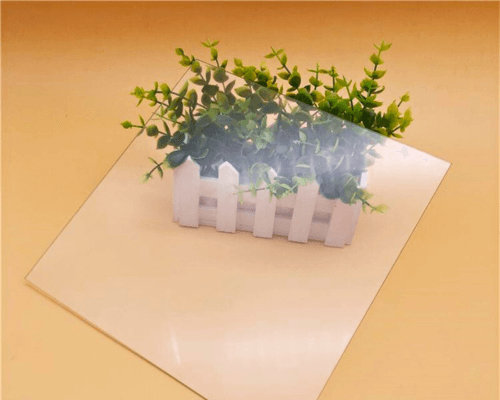

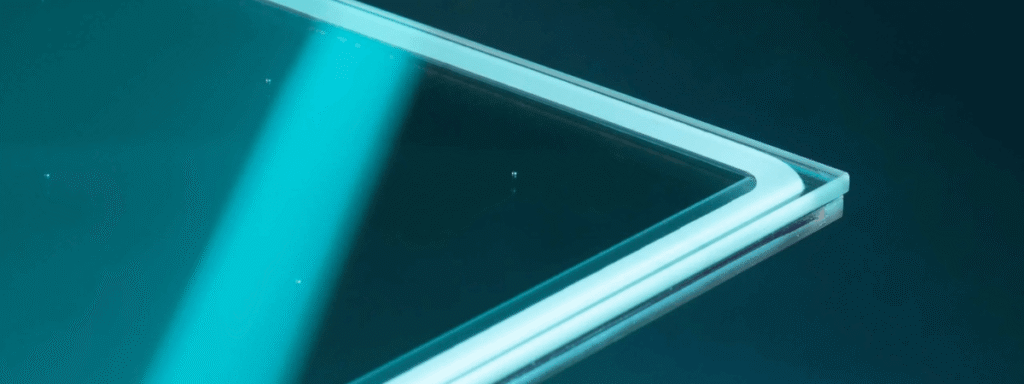

VIG operates like a transparent thermos. By creating a vacuum gap of just 0.1–0.2mm between two glass panes, it eliminates the air needed for heat transfer.

Microscopic pillars hold the gap open against atmospheric pressure, creating a super-thin, highly insulating barrier.

The Thermos Principle

Think about your morning thermos. How does it keep coffee hot for hours, even when it’s freezing outside? The secret is the vacuum between the thermos walls. Heat needs matter to travel through—air molecules bumping into each other, passing energy along. No air means heat has nowhere to go.

VIG applies this exact principle to windows. It’s a transparent thermos for your building.

How Traditional Glazing Falls Short

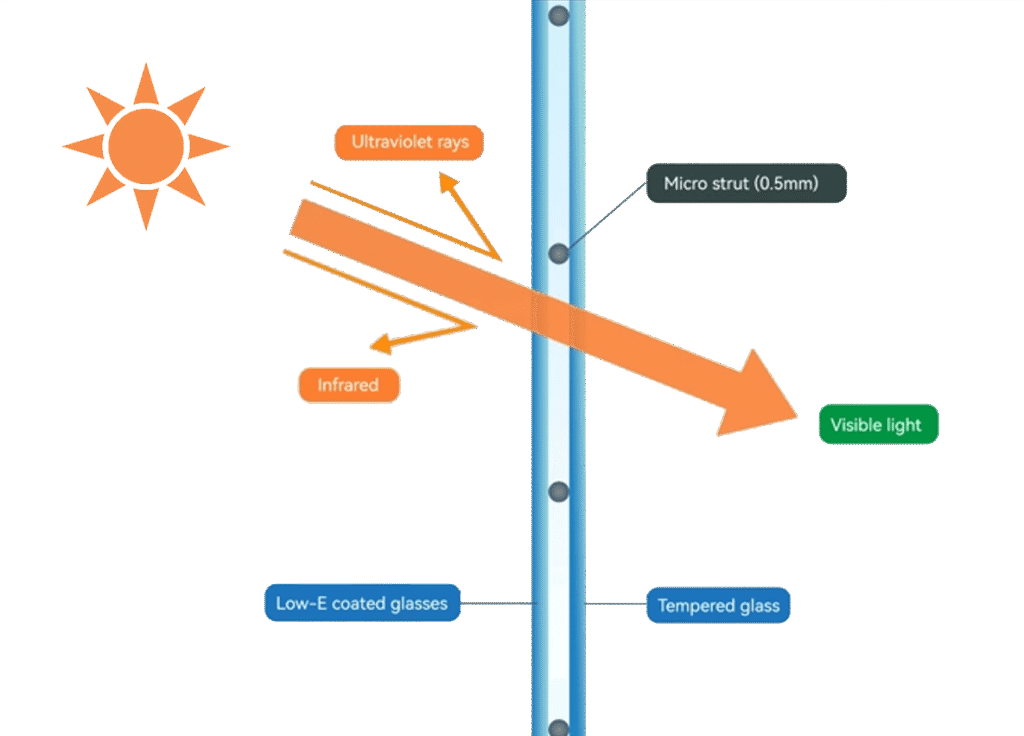

Traditional glazing uses wide cavities filled with gases like Argon or Krypton between glass panes. These gases are better insulators than air, but the molecules are still there, still moving, still carrying heat across.

VIG removes almost all the gas molecules. The gap between panes is microscopic—just one-tenth to two-tenths of a millimeter, about the thickness of a human hair.

The Engineering Solution to Atmospheric Pressure

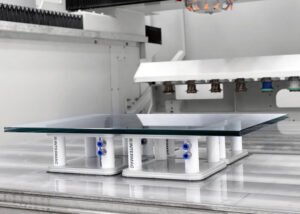

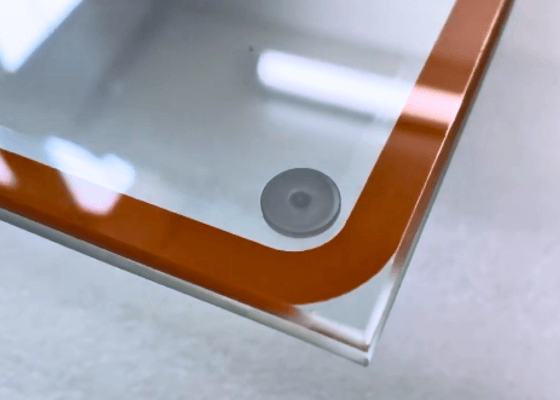

Now, you might be thinking: won’t atmospheric pressure just crush those panes together? That’s the right question. We’re talking about roughly ten tons of force per square meter trying to push the glass closed. This is where clever engineering comes in.

Manufacturers place a grid of tiny micro-pillars between the panes—usually three-tenths to five-tenths of a millimeter in diameter, spaced about twenty millimeters apart. They hold the panes at precisely the right distance to maintain the vacuum, but they’re small enough that from any normal viewing distance, they’re virtually invisible. They simply disappear against whatever you’re looking at through the window.

Hermetic Sealing Creates the Barrier

The edges are hermetically sealed, creating an environment where heat cannot transfer by conduction or convection because there’s nothing there to conduct it. The result is a glazing unit thinner than your smartphone that insulates better than a thick insulated wall.

1: Eliminate Cold Zones and Slash Heating Costs with R-20 Performance

Thermal Breakdown: While triple glazing tops out around R-8, VIG achieves a center-of-glass R-value of up to R-20. This massive jump in efficiency eliminates “chill zones” near windows, allowing for expansive glass facades that don’t tax the building’s HVAC system.

Understanding Thermal Density

Here’s a statistic that should make you pause: the thermal density of VIG is roughly three times better than triple glazing. But let me explain what that actually means, because “thermal density” is one of those phrases that sounds impressive but doesn’t mean much until you really think about it.

The R-Value Revolution

When we talk about insulation, we use something called an R-value. The higher the number, the better the insulation. Your typical wall in a modern home might have an R-value around 15 to 20. Standard triple glazing, which is currently considered high-performance, achieves an R-value of about 6 to 8.

To get there, it relies on two large cavities filled with gas—usually sixteen millimeters of gas in each cavity. That’s a lot of space dedicated to trapping heat.

Windows That Perform Like Walls

VIG changes the physics of the game entirely. Because heat cannot travel through a vacuum—there’s literally nothing there to carry it—the insulation value skyrockets. The latest units from manufacturers can achieve an R-value of up to twenty in the center of the glass. That’s right—a window that insulates almost as well as a solid insulated wall.

Real-World Comfort Transformation

Think about what this means for a moment. Those cold drafts you feel when you stand near a window on a winter morning? Gone. The “chill zones” near glass facades that plague even modern luxury buildings, where the heating system is running full blast but you still need a sweater if you sit by the window? Eliminated.

VIG creates a thermal barrier so effective that the inside surface of the glass stays close to room temperature, even when it’s freezing outside.

Design Freedom for Architects

For architects, this is revolutionary. It means you can design buildings with expansive glass facades that don’t become thermal liabilities.

You can have that gorgeous floor-to-ceiling transparency without forcing the HVAC system to work overtime compensating for heat loss. The window becomes part of the building’s thermal envelope instead of its weakest link.

2: Cut Structural Costs and Carbon Emissions in Half

Structural Savings: VIG weighs 20–25 kg/m ², compared to over 50 kg/m ² for triple glazing. This 50% weight reduction lowers costs for steel framing, motors, and foundations. Additionally, using fewer glass panes cuts the embodied carbon footprint by roughly half.

The Hidden Weight Problem

Let me tell you about a problem that doesn’t make it into the glossy architectural magazines.

Triple glazing is absurdly heavy. A standard triple-glazed unit often weighs more than fifty kilograms per square meter. Now, you might think, “Buildings are heavy anyway. What’s the big deal?”

The Cascading Cost Effect

Here’s the big deal: that weight cascades through the entire design like dominoes falling. You need heavy-duty steel framing to hold the glass. You need reinforced foundations to support that framing.

If you want operable windows—you know, windows that actually open—you need industrial-grade motors because no human is going to manually lift fifty kilograms of glass over their head. Suddenly, your beautiful window costs twice what you budgeted, and most of that cost isn’t even the glass itself. It’s everything you had to beef up to support it.

Lightweight Performance

VIG solves this problem by doing more with less. According to data from Guardian Glass, a VIG unit typically weighs twenty to twenty-five kilograms per square meter. That’s less than half the weight of triple glazing. In fact, it weighs about the same as a single pane of regular glass.

Let that sink in for a second. You’re getting three times the insulation with the same weight as the cheapest, simplest window you could install.

The Embodied Carbon Advantage

But the benefits go beyond just structural engineering. There’s also the carbon question.

VIG uses one-third less glass because it only needs two panes instead of three. Manufacturing glass is an energy-intensive process—you’re melting sand at temperatures above fourteen hundred degrees Celsius. Every pane you don’t need represents a significant reduction in embodied carbon.

The numbers are striking: VIG has an embodied carbon footprint of roughly twenty-four and a half kilograms of CO2 per square meter, compared to nearly fifty for triple glazing.

Meeting Carbon Neutrality Goals

This matters tremendously for projects aiming for carbon neutrality. We often focus on operational carbon—the energy buildings use once they’re occupied. But embodied carbon, the emissions from manufacturing and transporting materials, can account for up to half of a building’s lifetime carbon footprint.

By switching to VIG, you’re cutting your window’s carbon impact in half before the building even opens its doors.

3: Achieve Ultra-Slim Profiles and Maximize Natural Light

Aesthetic Edge: At just 8.3mm thick (vs. 40mm+ for triple glazing), VIG enables the “frameless” minimalist look architects crave. With only four glass surfaces instead of six, it also offers higher light transmission for clearer, brighter views.

The Aesthetic Challenge of Modern Architecture

Modern architecture has been moving toward minimalism for decades now. Clean lines. Slender profiles. That sense of the boundary between indoors and outdoors just dissolving away. Triple glazing fights against this aesthetic at every turn.

Why Triple Glazing Creates Bulky Frames

To understand why, let’s talk about thickness.

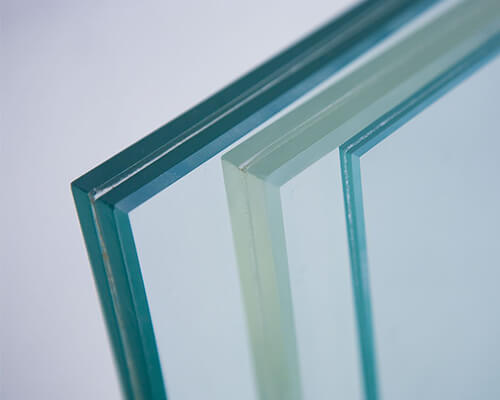

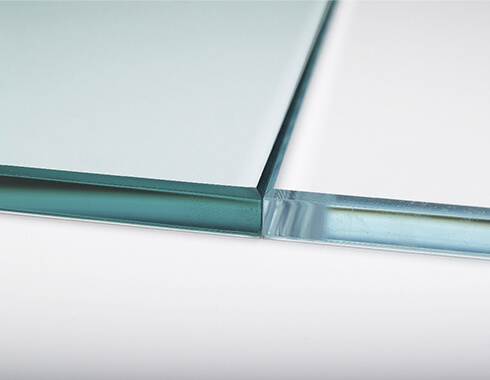

Triple glazing typically requires a stack depth of thirty-six to forty-four millimeters. That’s the total thickness of all three panes of glass plus the two gas-filled cavities between them. Now, when you’re trying to install this into a window frame, you need frames that are chunky enough to hide that thick edge of glass.

The result is bulky frames that announce themselves, that draw attention to the separation between inside and outside rather than minimizing it.

Credit Card Thickness

VIG restores architectural freedom in a dramatic way. Standard VIG units are approximately eight and three-tenths millimeters thick. Some specialized units can be as thin as six and seven-tenths millimeters. We’re talking about the thickness of a few stacked credit cards.

The Frameless Look Architects Dream About

This thinness allows for ultra-slim window profiles—the kind of “frameless” look that modern architects dream about but could never quite achieve with triple glazing.

Suddenly, you can have windows that look like simple sheets of glass, where the frame recedes into near-invisibility.

Brighter, Clearer Views

But there’s another advantage that comes with having fewer panes of glass, and it’s one that might not be obvious at first. Light transmission.

Every time light passes through a pane of glass, a small percentage of it is reflected or absorbed. With triple glazing, you’ve got six surfaces for light to interact with—six opportunities for light loss. VIG only has four surfaces. The difference is noticeable.

VIG offers superior visible light transmission, which means occupants get a clearer, brighter, more truthful view of the outside world. The view isn’t dimmed or muted by an extra pane of glass. It’s like the difference between looking through a clean window versus one that’s been there for a few years accumulating that subtle haze.

Daylighting Benefits

For buildings where daylighting is important—which should be every building, really—this improved light transmission means less reliance on artificial lighting during the day, which brings us back to energy savings from another angle entirely.

4: Block Urban Noise Without Adding Weight

Acoustic Control: Sound waves require air to travel; the vacuum in VIG stops them dead. VIG excels at blocking low-frequency city drone, and “Hybrid” VIG units can achieve Sound Transmission Class (STC) ratings of 38+, outperforming standard glazing.

The Mass-Equals-Sound-Blocking Myth

There’s a common belief in acoustics that you need mass to stop sound.

Heavy materials block noise better than light ones, right? That’s generally true, which is why triple glazing is pretty good at noise reduction, typically achieving a Sound Transmission Class rating around thirty-seven.

Triple Glazing’s Resonance Problem

But here’s something interesting: triple glazing can actually struggle with certain types of noise, particularly low-frequency “city hum”—that constant drone of traffic, HVAC systems, and urban activity.

The gas-filled cavities between panes can create resonance issues where certain frequencies actually pass through more easily than others.

How Vacuum Stops Sound

VIG approaches sound differently. Sound waves, like heat, need a medium to travel through. They’re vibrations that propagate through air molecules.

In a vacuum, there are no molecules to vibrate. The sound simply has nowhere to go. It hits the outer pane, and while some vibration transfers through the glass itself and through those tiny support pillars, much of the sound energy is blocked by the absence of air.

Hybrid VIG: The Ultimate Acoustic Solution

But the real game-changer is something called “Hybrid VIG,” where a VIG unit is laminated to an additional sheet of glass.

This combination gives you the vacuum’s sound-blocking properties plus the mass of that extra pane. Hybrid VIG units achieve a Sound Transmission Class rating of thirty-eight, outperforming standard triple glazing while remaining significantly lighter.

A Different Quality of Silence

For projects in noisy urban centers, near airports, or facing highways, VIG creates what I can only describe as a “deadening” effect on noise. It’s not just that the sound is quieter—it’s that the quality of the silence is different. The constant background drone that you don’t even realize is affecting you until it’s gone? VIG removes it.

5: Install Once and Maintain Peak Performance for Decades

Durability: Gas-filled windows lose about 1% of their gas per year, slowly degrading their R-value. VIG relies on a permanent vacuum seal. With no organic sealants to degrade and no gas to leak, VIG units have an expected lifespan of 25–50 years.

The Hidden Degradation of Gas-Filled Windows

Here’s something most people don’t know about triple glazing: it has a shelf life.

Those noble gases sealed inside—the Argon or Krypton that provide the insulation—they leak out over time. It’s a slow process, typically about one percent per year, but it’s inexorable. After twenty years, your triple-glazed window has lost a significant portion of its insulating power. It still looks fine from the outside, but it’s not performing anywhere near the level it did when it was new.

No Gas Means No Leakage

VIG doesn’t have this problem because it relies on a vacuum, not gas. There’s nothing to leak out.

Either the hermetic seal holds and the vacuum remains intact, or the seal fails completely and you know immediately because the glass would show condensation or distortion. There’s no slow degradation, no gradual loss of performance that sneaks up on you.

Advanced Sealing Technology

Modern VIG units use sophisticated edge sealing technology—proprietary flexible metal seals and fully tempered glass. The seal is hermetic in the truest sense of the word.

And because there are no organic sealants to degrade over time from UV exposure or temperature cycling, VIG units have an expected lifespan of twenty-five to fifty years of full performance.

Long-Term Building Economics

Think about what this means for building economics. The windows you install today will still be performing at peak efficiency decades from now. You’re not looking at a replacement cycle every twenty years. You’re installing windows that might last as long as the building itself.

Questions You’re Probably Asking Right Now

Can you actually see those micro-pillars?

Technically yes, but they’re incredibly subtle. The pillars are usually three-tenths to five-tenths of a millimeter in diameter and spaced about twenty millimeters apart.

Here’s a useful comparison: hold your hand at arm’s length and look at it. Your hand is roughly one meter away, right? That’s about the distance most people view windows from. At that distance, those tiny pillars essentially disappear.

Your brain filters them out the same way it filters out the thin muntins in traditional divided-light windows. They fade into the background of whatever view you’re looking at through the glass.

Isn’t vacuum glass prohibitively expensive?

Currently, VIG is a premium product. It costs roughly three to five times more than standard double glazing. I won’t sugarcoat that—it’s a significant upfront investment. But let’s add some important context.

When you compare VIG to high-end triple glazing, the cost gap narrows considerably. And when you factor in the savings on structural steel due to the lighter weight, the reduced foundation requirements, and the long-term HVAC energy savings from superior insulation, the return on investment often justifies the upfront cost for high-performance projects.

We’re also seeing prices come down as manufacturing scales up. This is a technology that’s moving from boutique to mainstream, and that transition typically brings costs down significantly.

Is VIG actually safe?

Yes. Modern VIG units from reputable manufacturers use fully tempered glass, which is sometimes called toughened glass. If it breaks—which is rare—it shatters into small, relatively harmless pebbles rather than dangerous jagged shards.

It can also be laminated with an interlayer film for additional security and acoustic performance, just like any other architectural glass.

Can you retrofit VIG into older buildings?

This is actually one of VIG’s most exciting applications. Because VIG is only about eight millimeters thick, it can often fit into the original timber or steel frames of historic buildings, where twenty-four millimeter double glazing would never fit without major modifications.

This allows heritage properties to achieve modern energy efficiency standards without destroying their historical character or replacing original window frames. You can preserve the authentic look and feel of a period building while bringing it up to contemporary performance standards.

The Path Forward

Triple glazing was a necessary stepping stone. It proved that we could build energy-efficient buildings without sacrificing natural light. But it’s reached its limit. It forces us to build heavier, design chunkier frames, and accept compromised views—all in service of meeting energy codes.

Vacuum Insulated Glass removes the compromise. It offers R-twenty insulation in a package that’s seventy-five percent thinner and half the weight. For any modern development aiming for Passive House standards, LEED Platinum certification, or simply a stunning aesthetic that doesn’t sacrifice performance, VIG represents the superior path forward.

We’re watching a technology transition happen in real time. The era of bulky, heavy windows is ending. The era of the vacuum—of doing more with elegantly less—is beginning. And once you understand the physics of why it works so well, you realize this isn’t just an incremental improvement. It’s a fundamental reimagining of what a window can be.