Tinted glass is float glass manufactured with metal oxides (like iron, cobalt, or selenium) added directly to the molten mix. This creates a permanent color that absorbs solar heat and reduces glare, unlike peelable window films. It is a cost-effective, durable solution for improving energy efficiency and privacy in buildings and vehicles.

Introduction

Standard clear glass has a major flaw: it acts as a greenhouse, trapping heat inside your building.

Tinted glass is the industry’s solution. By filtering sunlight rather than just blocking it, it lowers cooling costs and protects interiors from UV damage.

For builders and wholesalers, however, choosing the right glass goes beyond picking a color. You need to understand the specs. This guide covers the essential physics, manufacturing details, and strategic purchasing advice to help you select the right product for your project without expensive mistakes.

What Exactly Is Tinted Glass?

To the uninitiated, “tinted glass” is often confused with “window tinting,” which is a plastic film applied to a window after it is installed. It is vital that we make a sharp distinction here.

Tinted Glass (technically known as Body Tinted Float Glass or Heat Absorbing Glass) is a permanent material modification. It is not a coating, and it is not a film. It is float glass that has had its chemical recipe altered during the manufacturing process.

Imagine a glass of clear water. If you paint the outside of the glass brown, that is a film. If you stir tea leaves into the water until the liquid itself turns brown, that is tinted glass. The color is “homogeneous,” meaning it runs through the entire thickness of the pane. Because of this, factory-tinted glass will never peel, bubble, or fade. It is as durable as the stone and steel that make up the rest of the building.

Its primary function is to act as a filter. By modifying the glass, we change how it interacts with the solar spectrum, allowing it to absorb heat and reduce glare while maintaining transparency.

How Is Tinted Glass Manufactured?

To truly appreciate the quality of this material, we have to look inside the furnace. The creation of tinted glass relies on the Float Glass Process, which is the gold standard for producing perfectly flat, distortion-free glass. However, creating a consistent tint requires a mastery of high-temperature chemistry.

The Melt and the Dopants

The process begins with the standard ingredients of glass: silica sand, soda ash, dolomite, and limestone. These are fed into a massive furnace heated to approximately 1600°C (2900°F). At these temperatures, the raw materials dissolve into a glowing, viscous liquid we call “the melt.”

This is where the transformation happens. To create tinted glass, manufacturers add “dopants”—specific metal oxides—into the mix.

- To create Green, we add Iron Oxide.

- To create Bronze, we introduce Selenium.

- To create Grey or Blue, we use precise combinations of Cobalt and Nickel.

This is a delicate operation. The metal oxides must melt and disperse evenly throughout the millions of tons of liquid glass. If the mixture isn’t perfectly stirred by the convection currents in the furnace, you get streaks. But when done correctly, the color becomes an intrinsic part of the atomic structure of the glass.

The Float Bath

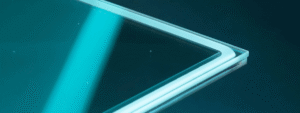

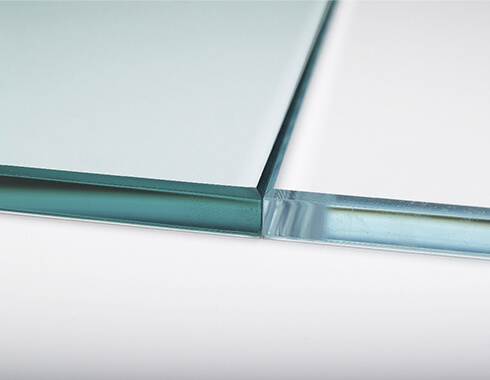

Once the chemistry is set, the molten glass flows out of the furnace and onto a bath of molten tin. Because glass is lighter than tin, it floats on top, spreading out like oil on water. Gravity pulls it flat, and the surface tension makes it perfectly smooth. This eliminates the need for polishing.

Annealing: The Stress Release

As the continuous ribbon of glass leaves the tin bath, it enters a cooling tunnel called a “lehr.” This step is critical for tinted glass. Because the glass now contains metal oxides, it holds heat differently than clear glass. It must be cooled slowly and evenly (annealed) to ensure there are no internal stresses trapped inside. Finally, it is cut into sheets, ready to be shipped to your warehouse or job site.

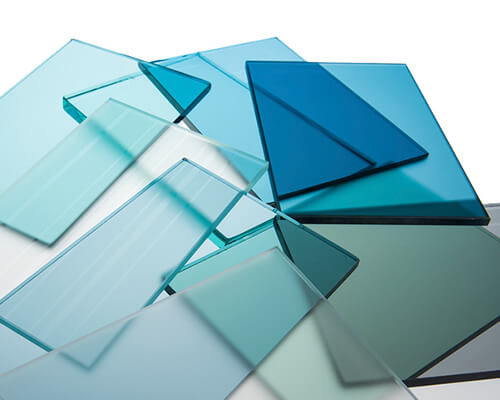

What Are the Standard Tinted Glass Colors?

In the global glass trade, a vague specification like “Blue” or “Bronze” is a recipe for disaster. The industry offers a sophisticated spectrum of saturation and hue, where slight shifts in chemistry result in drastically different aesthetic and thermal outcomes.

For the architect and the buyer, selecting a color is not merely about matching a paint swatch; it is about defining the mood of the interior light and the character of the building’s façade. Below, we explore the distinct families of the global color palette.

Bronze Tinted Float Glass: Warmth and Luxury

Bronze tinted glass is prized for its ability to filter harsh daylight into a soft, glowing interior ambiance, often creating a “sunset effect” that complements wood, stone, and brick structures.

The global standard-bearer for this family is Euro Bronze Tinted Float Glass. This is a subtle, reddish-brown tint—often described in the trade as “smoke bronze.” It is neutral enough for residential living spaces, cutting glare effectively without casting an aggressive orange hue over the interior.

However, for projects demanding a higher level of prestige, Golden Bronze Tinted Glass is the preferred choice. As the name implies, this variation carries a richer, stronger yellow-gold undertone. In direct sunlight, Golden Bronze appears more vibrant and luxurious, making it a staple for high-end hospitality projects and bank headquarters that wish to project stability.

For those requiring maximum privacy, Dark Bronze Tinted Glass offers a deep, chocolate-brown saturation. It creates a solid, monolithic look from the street and significantly lowers light transmission, making it ideal for regions with intense solar exposure.

Grey and Dark Grey Tinted Glass: Neutrality and Privacy

Architects often favor the grey spectrum for one specific reason: spectral neutrality. Unlike bronze or green, grey tinted float glass reduces the brightness of the sun without altering the true colors of the landscape. The sky looks blue, and the grass looks green; they are simply dimmer.

Euro Grey Tinted Float Glass is the classic choice here—a balanced “light grey” that fits nearly any architectural style, from modern apartments to commercial offices.

For a more contemporary edge, Blue Grey Tinted Glass offers a sophisticated hybrid. It combines the neutrality of grey with a cool, steel-blue undertone, designed specifically to harmonize with the concrete and steel elements of modern curtain walls.

At the extreme end of the spectrum lies Dark Grey Tinted Glass (often referred to as Super Grey or Black Glass). This tint is virtually opaque from the exterior, offering the highest level of privacy and heat absorption. It is heavily utilized in server rooms, automotive rear windows, and privacy partitions where visual obscurity is the primary goal.

Blue Tinted Float Glass: Clarity and Modernity

Blue tinted glass is the signature of the modern skyline, psychologically associated with cleanliness, technology, and airiness.

The most widely used variant is Ford Blue Tinted Glass (also known as Light Blue Float Glass). Named after its origins in the automotive industry, this is a crisp, pale sky-blue engineered for high transparency. It allows plenty of natural daylight to flood the interior while filtering out the infrared heat spike, creating a bright, uplifting environment.

However, not all blues are created equal. Ocean Blue Tinted Glass offers a more vivid, aquatic character with a slight teal influence, often found in coastal resorts or decorative features.

In contrast, Dark Blue Tinted Glass (sometimes called Diamond Blue) is a deep, intense navy. This is a “performance tint.” Because it is so much darker than Ford Blue, it absorbs a massive amount of solar heat, making it a functional necessity for commercial towers in tropical climates.

Green Tinted Float Glass: Nature and Performance

Green tinted glass naturally offers the best ratio of light transmission to heat blocking, thanks to the specific iron oxide chemistry used to create it.

French Green Tinted Float Glass (F-Green) is the industry standard for “natural” glass. It features the soft, emerald hue seen on millions of car windshields and eco-friendly buildings. It blends seamlessly with garden landscapes, making it the default choice for low-rise buildings that want to disappear into their surroundings.

For more aggressive shading, Dark Green Tinted Glass offers a heavy, forest-green saturation. It acts as a powerful filter, drastically reducing the solar heat gain coefficient while providing a bold, permanent aesthetic.

Specialty Colors: Pink Tinted Glass and Beyond

Beyond the “Big Four” architectural colors, there are niche tints used for specific design requirements. Pink Tinted Float Glass, for example, is a rare but distinct option. It produces a soft, rosy light that is incredibly flattering to skin tones, making it a secret weapon for high-end mirrors, salon interiors, and decorative partitions where a vintage or softer touch is required.

How Does Tinted Glass Actually Control Heat?

To sell or specify this glass, you must understand the mechanism at play. Tinted glass does not “bounce” heat away; it acts as a thermal sponge.

The Absorption Mechanism

When sunlight hits clear glass, most of the energy passes right through. But when sunlight hits tinted glass, the metal atoms (the iron, cobalt, or selenium we added) act like catchers’ mitts. They “catch” the photons of solar energy.

When the glass absorbs this energy, it converts it into heat. This means the glass pane itself gets hot—sometimes very hot. By trapping this heat in the glass, it prevents that energy from traveling directly into the room. The heat is then slowly released back to the outside (and a little bit to the inside), smoothing out the temperature spikes of the day.

What Are the Performance Properties of Tinted Glass?

When you are evaluating a glass shipment or specifying a façade, you aren’t just choosing a color; you are choosing a set of engineering data. To act as a true partner in a project, you must understand how these five properties dictate the building’s efficiency and cost.

1. Optical Properties: Light Transmission & Glare Control

The most immediate impact of tinted glass is optical. By reducing the Visible Light Transmission (VLT), tinted glass acts as a permanent filter. While clear glass typically allows about 90% of light through, tinted variants range anywhere from 15% to 70% depending on the color and thickness.

- Glare Reduction: Harsh sunlight makes computer screens unreadable and fatigues the eye. Tinted glass softens this light at the source, often removing the need for blinds in office environments.

- UV Absorption: It serves as a silent guardian for interior assets. By absorbing up to 99% of Ultraviolet (UV) radiation, it dramatically slows the fading of carpets, artwork, and retail merchandise.

2. Thermal Properties: Solar Heat Absorption

This is the defining characteristic that separates tinted glass from standard glazing. While Low-E glass is designed to reflect heat, tinted glass is designed for Solar Heat Absorption.

- The Heat Sponge Effect: Roughly 30% to 50% of solar energy is trapped within the glass substrate itself.

- Re-radiation: Once absorbed, the heat is dissipated back into the atmosphere (thanks to external airflow), resulting in a much lower Solar Heat Gain Coefficient (SHGC). This means the building’s air conditioning units don’t have to work as hard, directly lowering capital and operational costs.

3. Aesthetic Properties: Color Density & Uniformity

The visual identity of tinted glass is a result of pure chemistry. By introducing metal oxides—Iron for green, Cobalt for blue, Selenium for bronze—manufacturers create a color that is uniform through the entire body of the glass.

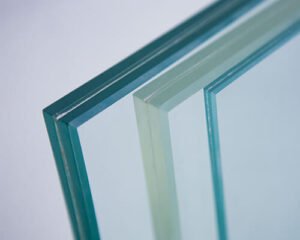

- Thickness Dependence: This is a critical factor for buyers. Because the tint is in the “body,” a 6mm sheet will always look darker than a 4mm sheet of the same mixture.

- The Business Implication: You generally cannot mix thicknesses on the same façade without creating a visible patchwork of different shades.

4. Mechanical Properties: Processing & Thermal Stress Risks

Physically, tinted glass behaves like clear float glass—it can be cut, drilled, and edged. However, it carries one specific risk profile: Thermal Stress.

- The Risk: Because the glass absorbs heat, it expands. If the center of the pane is hot (from sun) while the edges are cool (shaded by the frame), the tension can cause the glass to crack.

- The Solution: For professional applications, we almost always recommend that tinted glass be tempered (toughened). Once tempered, it becomes a versatile powerhouse suitable for lamination, double-glazing (IGUs), or hybrid Low-E coatings.

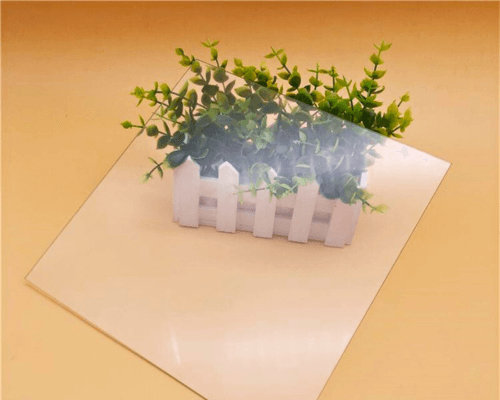

5. Privacy Dynamics: Daytime vs. Nighttime Visibility

A frequent requirement for residential projects is privacy. Tinted glass offers this through Visual Obscurity, but it is conditional.

- Daytime: Because exterior sunlight is brighter than interior lighting, the glass appears dark/opaque to outsiders.

- Nighttime: This is not a one-way mirror. If lights are on inside at night, the physics reverse, and the glass becomes transparent from the outside. For total nighttime privacy, curtains are still required.

Tinted vs. Reflective Glass: Which One Do You Need?

We often see confusion between these two product categories. While they both control sun, they do it in opposite ways.

Tinted Glass works by Absorption.

As we discussed, it soaks up the heat. Visually, it looks like a dark, transparent gemstone. It is soft on the eyes and allows you to see inside the building to some degree. It is subtle and integrates well with natural materials.

Reflective Glass works by Reflection.

Reflective glass has a metallic coating applied to the surface (either during the float process or afterwards in a vacuum chamber). This coating acts like a mirror, bouncing the sunlight and heat back into the atmosphere.

| Feature | Tinted Float Glass | Reflective Coated Glass |

| Mechanism | Absorbs Heat. Works like a sponge; the glass itself warms up. | Reflects Heat. Works like a mirror; bounces energy away. |

| Visuals | Transparent. “Smoked” colors (Bronze, Grey, Green). Natural view out. | Mirror-Finish. High reflectivity. Offers “One-Way” daytime privacy. |

| Standard Thickness | 3mm – 12mm (Most common: 4mm, 5mm, 6mm) | 4mm – 8mm (Coating usually applied to 5mm/6mm) |

| Standard Sizes | Flexible. From 2140x3300mm up to Jumbo (3300x6000mm). | Limited. Generally maxes out at 2440x3660mm due to coating lines. |

| Processing | Standard. Can be cut, edged, and tempered exactly like clear glass. | Specialized. “Soft-coat” types require edge deletion before sealing. |

| Applications | • Residential Windows • Interior Partitions & Balustrades • Furniture (Tabletops) | • High-Rise Curtain Walls • Commercial Facades • Extreme Climate Glazing |

Where Is Tinted Glass Most Commonly Used?

Residential Architecture

Homeowners generally dislike the “corporate office” look of reflective glass. They want natural views. Tinted glass (especially Euro Bronze or French Green) is ideal here. It protects the home from overheating without sacrificing the connection to the outdoors.

Commercial Curtain Walls

For skyscrapers and office parks, tinted glass is a staple. It reduces the cooling load on the HVAC system, which saves the building owners millions of dollars over the lifespan of the structure. It also creates a comfortable working environment by reducing the contrast between the bright window and the dark office interior.

Automotive Industry

The automotive sector is the largest consumer of tinted glass. The windshield is almost always light green (to meet legal visibility standards while cutting heat), while the rear windows use dark grey or black privacy glass to keep the passengers cool and hidden.

The Professional Checklist To Wholesale Tinted Glass

If you are an importer bringing in containers or a developer procuring for a skyscraper, the difference between a successful project and a costly nightmare often lies in the details. Tinted glass requires more specific attention than clear glass.

Use this 4-point checklist to ensure your order is flawless.

1. The “Color-Density” Check (Thickness Matters)

This is the most common mistake in the industry. Because the color is in the glass, the thickness determines the darkness.

- The Rule: A 6mm sheet of Grey glass is significantly darker than a 4mm sheet of the same Grey glass.

- The Action: Never approve a sample in one thickness (e.g., 5mm) if you plan to order a different thickness (e.g., 10mm). Always request a sample in the exact thickness you intend to build with.

2. The “Single Batch” Strategy (Consistency)

Tinted glass is a chemical product. Slight variations in the furnace temperature or the raw material mix can shift the hue slightly between production runs.

- The Risk: If you buy “Euro Bronze” in January for the ground floor and “Euro Bronze” in June for the top floor, they might not match perfectly.

- The Action: Calculate your total project volume upfront. Require your supplier to source the entire quantity from a single production campaign (batch). If the project is phased, set aside the glass for later phases immediately to ensure color continuity.

3. The Thermal Safety Assessment (Tempering)

Tinted glass gets hot—much hotter than clear glass. If you install annealed (standard) tinted glass in a frame where the center is exposed to hot sun and the edges are shaded, it can crack due to “Thermal Stress.”

- The Rule: The darker the tint, the higher the risk.

- The Action: For any tint with a Light Transmission (VLT) lower than 50% (such as Dark Blue, Dark Green, or Golden Bronze), tempering is mandatory. Do not cut corners here; annealed dark glass will likely break in direct sunlight.

4. Logistics and Storage (Moisture Control)

Glass acts like a sponge for moisture during sea freight. If tightly packed sheets get wet, “glass corrosion” (white staining) can occur, ruining the aesthetic surface.

- The Action: Verify that your supplier uses high-quality interleaving powder (anti-mold powder) between every sheet and includes desiccant bags in the crates. Once delivered, never store crates of tinted glass outdoors in the sun; the heat buildup inside the pack can cause breakage before installation.

Conclusion

Tinted glass is a remarkable fusion of chemistry and utility. It allows us to build with light without being ruled by it. Whether you choose the warm elegance of Euro Bronze, the clean modernity of Ford Blue, or the natural performance of French Green, you are choosing a material that actively works to make the building better.

For the buyer and the builder, the key is to respect the physics. Understand that darker means hotter glass. Understand that thickness changes color. And understand that when used correctly, tinted glass is one of the most cost-effective energy upgrades available in modern construction.

Frequently Asked Questions (FAQs)

Q: Does tinted glass provide privacy at night?

A: No, and this is a common misconception. Privacy depends on lighting conditions. During the day, the glass is darker than the outside, so it’s hard to see in. At night, if you turn your lights on, the effect reverses. You will see your own reflection, and people outside will see you clearly.

Q: Can I just buy clear glass and add a film later?

A: You can, but it is a short-term solution compared to tinted glass. Window films are plastic; they can scratch, peel, and degrade over 10 to 15 years. Tinted glass is permanent. The color is the glass itself, so it will last as long as the building stands.

Q: Is tinted glass expensive?

A: Tinted glass is generally more expensive than standard clear glass, but it is usually cheaper than high-performance reflective or Low-E coated glass. It sits in the “mid-range” of architectural glass pricing, offering excellent value for the performance it delivers.

Q: Why does my tinted glass feel hot to the touch?

A: That means it is working! Tinted glass blocks heat by absorbing it. The glass acts as a shield, holding the heat so it doesn’t pass into your room. This is why we recommend tempering the glass—so it can handle that heat without risk of cracking.