Safety Glass refers to processed glazing materials specifically engineered to minimize the risk of injury upon impact or breakage. Unlike standard annealed float glass, which fractures into sharp, jagged shards capable of causing severe lacerations, safety glass is manufactured to either crumble into small, relatively harmless granules (fully tempered) or remain bonded to an interlayer, retaining the fragments within the opening (laminated).

Functionally, safety glass is mandated in critical locations where human impact is foreseeable—such as entrance doors, low-level glazing, balustrades, and shower enclosures—or where falling glass poses a hazard, such as overhead canopies and skylights. The primary objective is to transform the glass from a fragile, brittle material into a structural element that prioritizes occupant safety without compromising optical clarity.

Technical Principles

The classification of «Safety Glass» is achieved through two distinct manufacturing processes, or a combination thereof. It is defined by adherence to regulatory standards such as CPSC 16 CFR 1201 (USA), EN 12600 (Europe), or ANSI Z97.1.

1. Thermally Toughened (Fully Tempered) Glass

This process involves heating float glass to its softening point (approximately 620°C) and then rapidly cooling (quenching) the surfaces with air jets.

- Stress Profile: This process locks the outer surfaces into a state of high compressive stress (typically exceeding 10,000 psi or 69 MPa), while the core remains in tensile stress.

- Breakage Mechanics: The stored energy in the tension core ensures that if the compression layer is penetrated, the entire sheet disintegrates instantly into small, cuboid fragments (dicing), significantly reducing laceration risks.

- Differentiation: Note that Heat Strengthened glass (surface compression between 3,500 and 7,500 psi) is not classified as safety glass unless laminated, as it breaks into large shards similar to annealed glass.

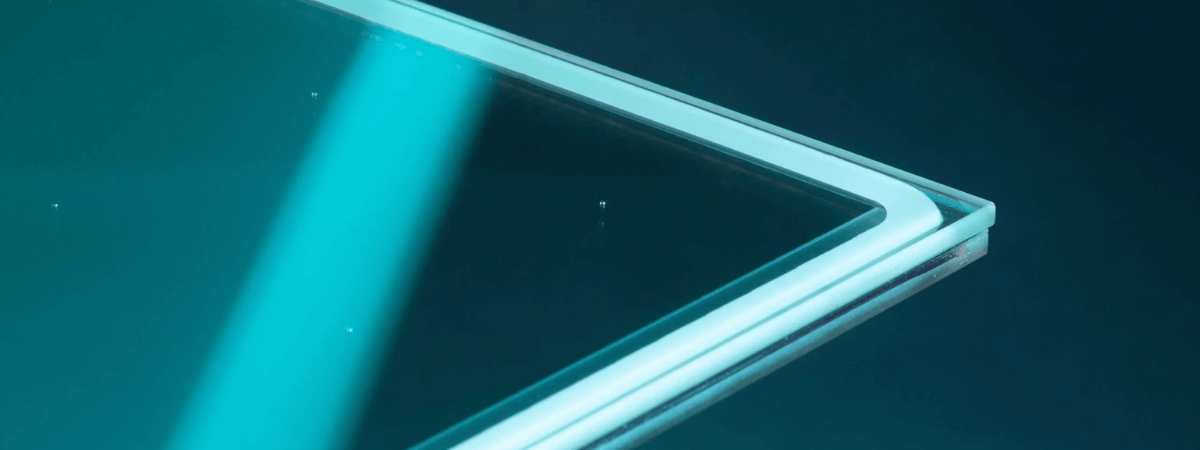

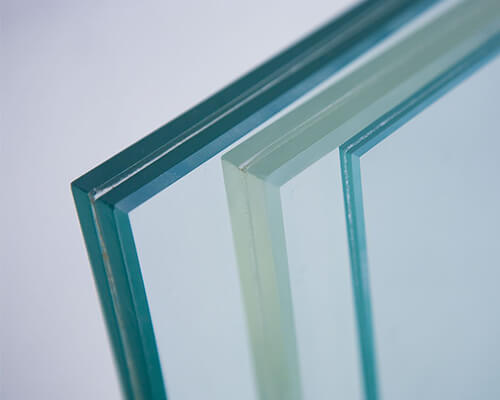

2. Laminated Safety Glass

Lamination involves bonding two or more lites of glass together using a polymeric interlayer, processed under heat and pressure in an autoclave.

- Interlayers: Common materials include PVB (Polyvinyl Butyral) for standard safety and acoustic damping, or SGP (Ionoplast) for high-structural demands requiring greater stiffness and post-breakage strength.

- Retention: Upon fracture, the glass fragments adhere to the interlayer. This maintains the structural integrity of the barrier (containment), preventing penetration by the impacting object and preventing glass fallout.

Specification Notes

When specifying Safety Glass for high-performance façades, relying solely on standard compliance is often insufficient to guarantee longevity and visual fidelity. The following points address common failure modes and quality distinctions:

- Spontaneous Breakage & Heat Soaking:

Fully tempered glass contains a inherent risk of spontaneous breakage due to Nickel Sulfide (NiS) inclusions. For inaccessible areas or high-altitude glazing, specifications should mandate Heat Soak Testing (HST). This destructive test accelerates the phase change of NiS inclusions, causing defective panels to break in the factory rather than on-site. - Optical Distortion (Anisotropy & Roller Wave):

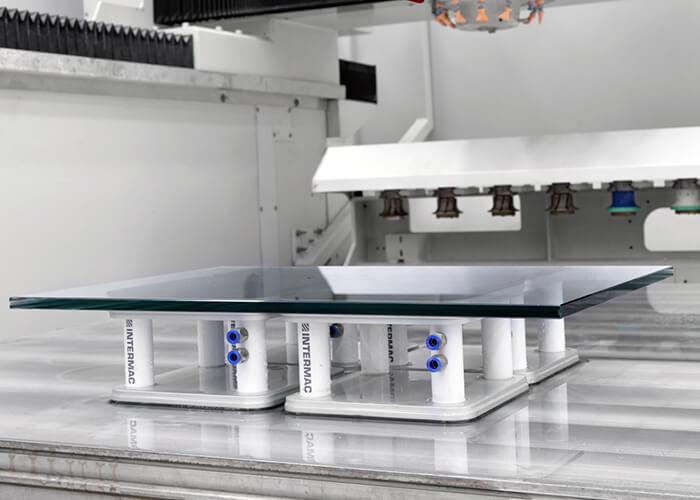

The tempering process can introduce visual distortions. «Roller wave» creates a rippled reflection, while «anisotropy» (or iridescence) manifests as leopard spots visible under polarized light.- Advisory: Define strict tolerances for roller wave (e.g., <0.10mm peak-to-valley) and specify edge dip limitations. At Hexad, we utilize online anisotropy scanners to quantify birefringence, ensuring it remains below visible perception thresholds for architectural applications.

- Interlayer Selection & Edge Stability:

For exposed edges or structural applications (e.g., glass fins, balustrades), standard PVB is susceptible to moisture ingress, leading to delamination or «edge bloom.»- Advisory: Specify Ionoplast (SGP) interlayers for open-edge applications to ensure edge stability and superior post-breakage retention. Ensure the laminating facility maintains strict humidity control (clean room standards) to prevent moisture entrapment during assembly.

- Dimensional Tolerances in Laminates:

«Stepped edges» occur when laminated plies are not perfectly aligned. This complicates silicone application and installation into channels.- Advisory: Require a mismatch tolerance of <1.0mm for high-end applications. Precise CNC cutting and automated lay-up lines are required to achieve this consistently.