Architectural Glass / Shower Glass

Shower Glass Supplier

20 years of manufacturing experience. Precision processing for importers and contractors. Custom sizes, CNC cutting, and secure export packing. Get a quote today.

Certifications

ISO 9001:2005 | TUV Verified

Complete Shower Glass Solution

Streamline your sourcing with our fully integrated product range. From high-volume standard safety panels and custom decorative finishes to compatible mounting hardware. Hexad provides a certified, one-stop solution for importers and contractors worldwide.

Tempered Safety Glass

Our core offering includes standard Clear and Ultra-Clear (Low Iron) glass, tempered to international safety standards for maximum impact resistance and optical clarity.

Decorative & Privacy Glass

Elevate your designs with our custom aesthetic series. We manufacture Acid Etched (Satin), Sandblasted, Fluted textures, and Tinted Grey/Bronze options for modern bathrooms.

Installation Hardware

Ensure a perfect fit with our range of heavy-duty 304/316 Stainless Steel hinges, clamps, handles, and seals, designed specifically to match our glass specifications.

On-Demand Shower Glass Solution

Our shower glass is manufactured to strict tolerance levels to ensure seamless installation. We combine heavy-duty impact resistance with optical clarity and CNC-precision cutouts.

- Glass Thickness: 6mm, 8mm, 10mm, and 12mm (1/4" to 1/2")

- Glass Options: Clear tempered, Ultra clear, Tinted series, Privacy glass

- Size Tolerance: Strict cutting tolerance for precise enclosure fitting

- Edge Work: High-gloss Flat Polish (Arris) or Pencil Edge

- CNC Processing: Water-jet hinge notches and Mickey Mouse cuts

- Drilling: Standard or Countersunk holes for flush hardware

- Treatment: Self-cleaning coating available

- Safety Certification: ISO, CE, SGS and TUV reports

Versatile Applications for Shower Glass

Our tempered shower glass is engineered for durability and elegance. Whether for luxury hotel projects, residential developments, or wholesale distribution, we supply high-precision shower glass tailored to you.

One-Stop Shower Glass

Solutions for Your Business

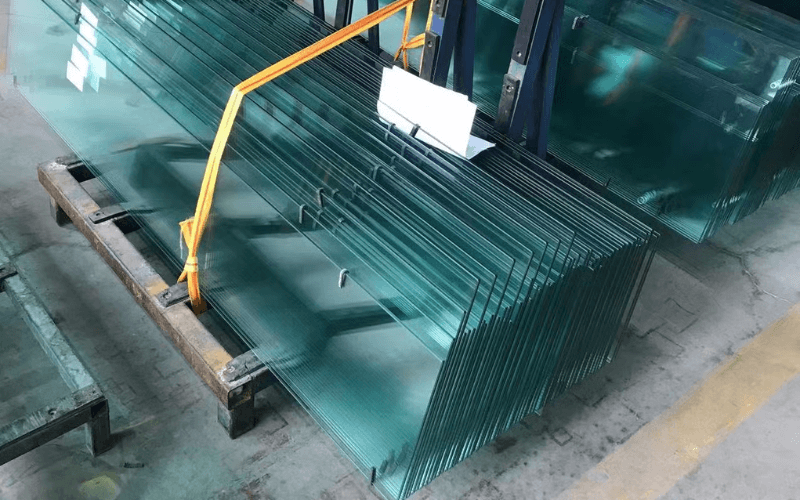

Whether you are stocking a warehouse or supplying a large hotel project, Hexad has the production capacity to meet your needs. We manufacture shower glass in all key configurations, including flat, curved, frosted, and ultra-clear low iron options.

Simplify your supply chain by leveraging our hardware integration services. We can supply compatible, high-quality hinges, handles, and seals alongside your glass. This ensures a perfect fit for every installation and reduces your total import costs.

Efficient Production Turnaround

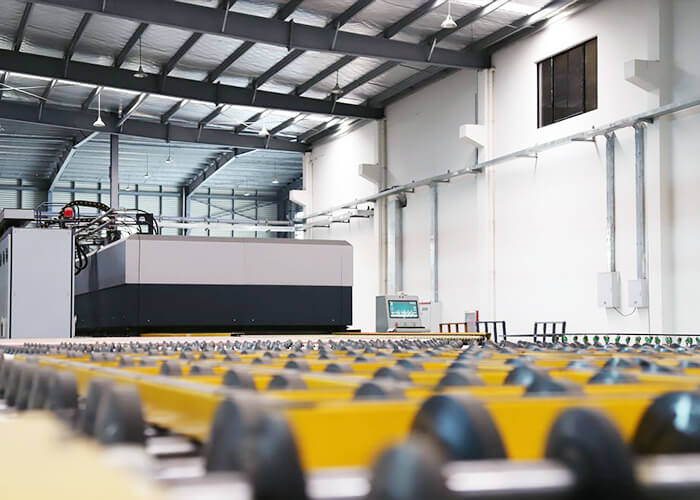

We combine precision engineering with rapid production capabilities. From CAD verification to final tempering, our 4-step process ensures your custom shower glass orders are accurate, on time, and ready for global export.

STEP 1

Consultation & Quote

Send us your size list or CAD drawings. Our engineers immediately review your requirements—including cutout details, hole positions, and edge types—to provide a precise, competitive quote within 12 hours.

STEP 2

Contract & Deposit

We double-check every technical detail to ensure 100% accuracy before finalizing the Proforma Invoice (PI). Once the deposit is received, your production slot is immediately locked in to guarantee the fastest lead time.

STEP 3

Mass Production

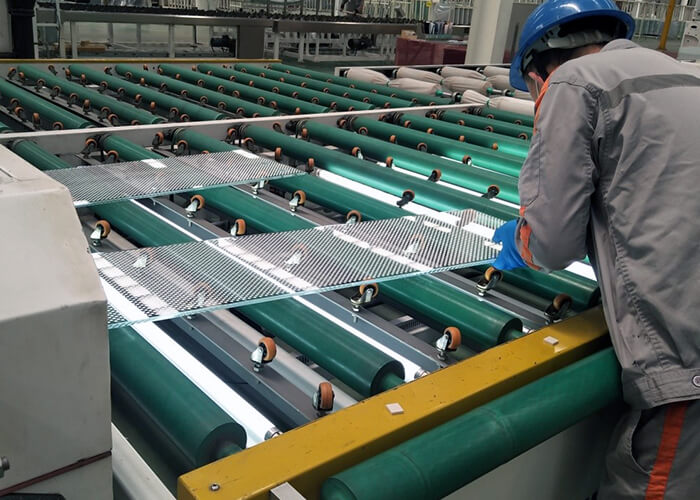

Production begins with precision cutting, edge polishing, and CNC drilling for hinges/handles. The glass is then tempered to safety standards. Our strict QC process verifies dimensions and fragmentation before the glass leaves the line.

STEP 4

Packing& Shipping

Finished panels are inspected and packed with protective corner guards and cork separators inside seaworthy plywood crates. We manage the container loading and logistics to ensure your goods arrive safely and on schedule.

Export-Grade Packaging

& Secure Logistics

For importers of finished tempered shower glass, arrival condition is non-negotiable. Unlike raw sheets, processed glass requires precision protection to preserve polished edges and custom cuts.

We go beyond standard crating. Each glass panel is separated by cork pads or mildew-proof paper to prevent friction scratches. We apply specialized plastic corner protectors to vulnerable edges before securing them in strong, seaworthy plywood crates.

Our logistics team professionally braces every crate with steel belts within the container, ensuring your custom glass arrives intact and ready for immediate installation.

Why More Than 620+ Clients

Over The World Love Work with Us?

Saving Your Time

By our advanced equipment and efficient production processes, the delivery time is 40% faster than other factories.

Saving Your Cost

You will save 60-80% of the cost because of our excellent production capacity and cost control. However, we only insist on making high-quality products.

Reduce Your Risk

You will reduce risk and 70% works, because our one-stop services will short your supply chain, our premium quality will make you worry-free.

What Our Clients Are Saying About Us

Frequently Asked Questions (FAQ)

We ensure our glass meets the strictest global safety standards for your market. Our tempered glass is certified to EN12150 (Europe), ANSI Z97.1 (USA), AS/NZS 2208 (Australia), and SGCC standards.

Just feel free to tell us your comply requirement, we provide full documentation with your shipment to ensure smooth customs clearance and local code compliance.

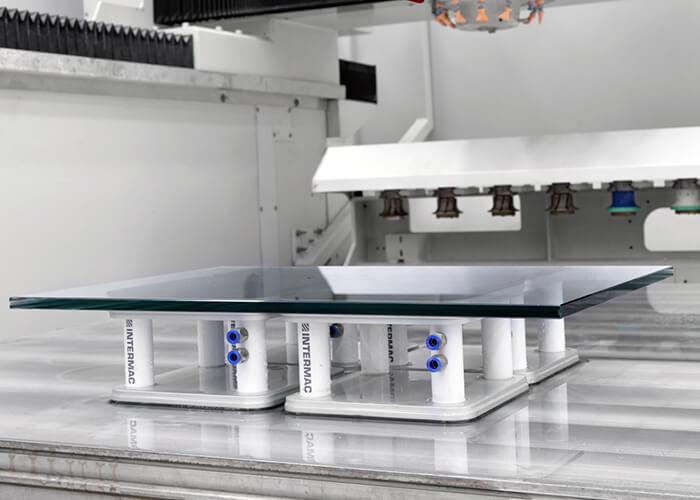

Yes. We specialize in precision deep processing.

Our advanced CNC machines allow us to cut precise hinge notches, handle holes (mickey mouse cuts), and polished edges to your exact CAD drawings. We guarantee a tolerance of ±1mm to ensure your hardware fits perfectly during installation.

We use secure, seaworthy plywood end-caps with paper interleaving between sheets to prevent scratching and moisture damage. The crates are reinforced with steel banding to container to ensure stability. Single set carton packaging is also available.

You can also share us with your packaging requirements, we will do anything to help your business. We have successfully exported to over 40 countries with a near-zero breakage rate.

We are flexible to support your business growth. While our most competitive pricing is for Full Container Loads (FCL), we also accept Less than Container Loads (LCL) for trial orders or smaller projects.

Contact our sales team to discuss the best volume for your needs.

For standard tempered shower glass orders, our production time is typically 7 to 15 days after confirming your drawings and deposit.

For urgent project deadlines, we offer “Rapid Solution” expedited services—please let us know your timeline upfront.

Yes, we can act as your one-stop supplier.

We can source and ship high-quality stainless steel or brass shower hardware along with your glass crate. This saves you shipping costs and ensures all components are compatible.

Additional Resources

Understanding CNC Cutouts for Shower Hardware

Why precision water-jet cutting is essential for the perfect fit of hinges and handles.

Read Guide

Privacy Glass Trends: Acid Etched vs. Sandblasted

Compare durability, texture, and fingerprint resistance for modern obscure shower designs.

Read Guide

Self-Cleaning Glass: The Nano-Coating Advantage

How hydrophobic coatings resist stains and increase product value for your end-customers.

Read Guide

Are you looking for an accurate quote?

No matter your project is complicated or simple, you will get an accurate quotation within 6 hours.

Request a Quick Quote (Response in 12 Hours)

We’d love to hear from you! Send us a message using the form opposite, or email us directly via sales@hexadindustries.com.

Starting from 2005 in China, HEXAD helps wholesalers and brand owners fulfill their building glass wholesale by top-end solutions.

- Free Technical Support

- Professional Production

- 80% 1-2 weeks Shipping

- Fast Response